Product Design

Our Products

Advantage TMS Learn About our Products

Advantage TMS represents a broad line of ultrasonic transducers, and piezo products with both open and closed face construction. Available operating frequencies range from 25 kHz to 320 kHz. Available beam angles range from a narrow 7 degrees to a maximum of 125 degrees.

Specialized Piezoelectric Transducers

Open-faced piezo transducers consist of a piezo ceramic bender element disc, with a conical shaped quarter wavelength metal radiator bonded to its center. This assembly is placed in a cylindrical metal or plastic housing with open grill. The rear of the housing is sealed with metal or plastic. (more info)

This transducer design produces an excellent receive sensitivity, and a wider bandwidth at high sound pressure level outputs. It remains stable with changes in temperature and humidity, and is also a good choice for CW (continuous wave) mode of operation.

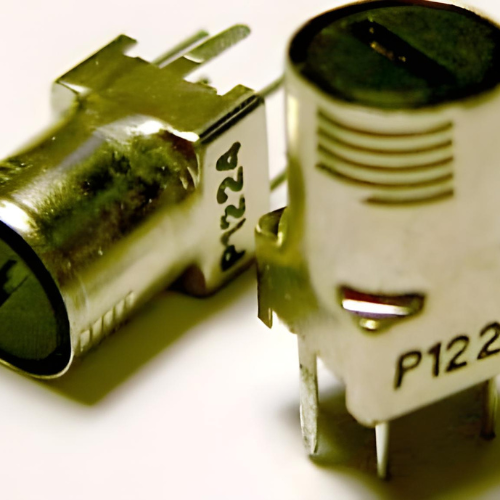

Closed faced transducer design consists of a piezo ceramic bender element disc bonded to the base of a cylindrical metal housing enclosed at one end, which acts as a diaphragm. The other end of the housing is sealed with a resin to complete the environmental package. This design works well for harsh and outdoor type environments. (more info)

Open and closed faced transducers are also made in a pulse transmit configuration. One transducer is used for both transmitting and receiving. This configuration help simplifies the design for echo ranging applications.

Other specialized construction transducers include mirror bender configuration, glass filled and silicon rubber faced transducers.

Mirror bender transducers have a transmitter and receiver element mounted in the same housing. The mirror bender portion describes the wave-guide path that gives these transducer unique properties. This wave-guide allows the transducer to detect objects at close ranges in a compact configuration when compared to separate transmitter receiver transducer pairs. (more info)

Glass filled transducers have an epoxy impedance matching layer on the face of the transducer and is typically used with high frequency transducers (125+ kHz) to improve the coupling of the ultrasonic wave to the air medium. The high frequency of the transducer provides a narrow beam angle when compared to lower frequencies and improves resolution when performing range measurements. (more info)

Silicon rubber faced transducers are environmentally rugged and resistant to harsh chemicals make them well suited to industrial type applications. They are available in a variety of sizes, frequencies and beam angles. The fully sealed construction allows them to meet Nema 4x, 6p, and IP67 requirements. (more info)

Advanced Sensor and Transducer Technologies

New Electrostatic transducers offer exceptional sensitivity and performance when detecting soft less reflective type target such as people, clothing and other porous materials. The construction of the transducer is similar to that of a capacitor having two plates, one fixed and one able to flex. Between the two plates is an insulating polyester material with a conductive metalized coating on one side forming the second plate.

A modulated high frequency electric potential is applied between the two plates and the flexible plate is attracted to and repelled from the fixed plate at the modulated frequency. This mechanical motion intern generates an ultrasonic acoustic wave pulse in front of the transducer, thus acting like a speaker.

After transmitting, a residual DC bias voltage remains on the two plates. When a returning ultrasonic pulse impacts the flexible plate the voltage between the two plates varies in proportion to the applied acoustic wave. The transducer now acts as a microphone and the acoustic wave can be detected as a electrical signal. The high sensitivity of electrostatic transducers is the result of the low mechanical mass of the flexible plate. (more info)

Atomizing transducers & Micro Nozzle transducers take advantage of the piezo effect to transfer mechanical energy at ultrasonic frequencies into liquids. The transducer, in contact with the liquid, produces a very fine mist with particle sizes as small as 3 μm. These transducers are well suited for a number of products and applications in the industrial, commercial and consumer fields as humidifiers, inhalators and nebulizers. (more info)

PVDF film sensors (polyvinylidene fluoride) are made from a special piezo film that generates electrical signals when subject to mechanical stress or thermal changes. Unlike piezo ceramics this material can be made into thin and very flexible sheets of almost any size or shape. This malleability makes this material ideally suited for a wide variety of sensor applications including light sensors, heat sensors, motion detectors, impact switches, keypads, accelerometers, vibration sensors, strain gauges, acoustics and flow meters. (more info)

New support electronics & components:

Sonar Ranging Module, Custom Sonar ASIC, and Impedance Matching Transformers have been added to the wide selection of products & services offered by Prowave Electronics and Advantage TMS Inc.

New The highly integrated design of the SRM400 ranging module, featuring the new PW0268 Custom Sonar ASIC, simplifies the process for creating a ranging system. Only three wires are needed to perform this function, ground, power and control. Once initiated through the control input, the module transmits the ultrasonic burst signal to drive the transducer. The control line then reverts to the receive mode, waiting for a returning echo signal from the transducer. The module identifies, amplifies and processes a valid returning echo signal, then drives the control line high. In order to get a range measurement, the user simply measures the elapse time between these two events. Knowing the speed of sound in air (342 m/sec.) this time can be converted into distance.

Discreet digital circuits or a microprocessor can be used to initiate the ranging module, and time the returning echo. This cost effective module is easily integrated into your latest hobby project or OEM product. (more info)

New The PW0268 Custom Sonar ASIC can be used as the core for designing your own ranging module. With a few external components, this chip incorporates all of the necessary functions: Internal voltage regulation, temperature compensation, transmits circuitry, two stages of pre-amplification, one stage of time control variable again amplification, high and low band pass filtering, detection and signal processing. This level of integration cuts the cost of product development and reduces the time required to bring products to market. (more info)

Impedance Matching Transformers complete the design package, making it easy to impedance match the transducers to a variety of drive circuits and source voltages. (more info)

The Reverse Parking Aid integrates the SRM400 series module and environmentally rugged transducer into an exceptionally compact configuration. Originally designed for automotive applications, this packaging works well with a number of other related applications that require vision assist, navigation, or collision avoidance in robotics and other mobile automated guided vehicles. (more info)

Bolt Clamped High Power Transducers are characterized by providing large displacement at high efficiency and low heat generation. Typical applications include ultrasonic cleaning, welding, bonding, drilling, etching, and engraving. (more info)

Special applications:

Other piezo-based products and services are available through Prowave Electronics and Advantage TMS Inc, including Glass Break Detectors, Piezo Buzzers and Sirens, Blood Pressure Sensors, Automotive Intrusion Alarm Sensors/Assembled Units with Harness and Piezo Ceramic Elements. (more info)

If you do not see what you are looking for please feel free to contact us with your special request.

Open Face Transducers

| Model Number | Description | Center Frequency (KHz) | Sensitivity Or SPL (min.) | Bandwidth (-6dB) (KHz) | Capacitance At 1KHz (pF) | Max. Continual Driving Voltage |

|---|---|---|---|---|---|---|

| 250ST160 | Transmitter | 25.0±1.0 | 112dB at 25.0KHz | 2.0 | 2400±20% | 20Vrms |

| 250SR160 | Receiver | 25.0±1.0 | -65dB at 25.0KHz | 2.0 | 2400±20% | 20Vrms |

| 250ST180 | Transmitter | 25.0±1.0 | 112dB at 25.0KHz | 1.5 | 2400±20% | 20Vrms |

| 250SR180 | Receiver | 25.0±1.0 | -65dB at 25.0KHz | 1.8 | 2400±20% | 20Vrms |

| 250ST240 | Transmitter | 25.0±1.0 | 115dB at 25.0KHz | 1.5 | 2400±20% | 20Vrms |

| 250SR240 | Receiver | 25.0±1.0 | -63dB at 25.0KHz | 1.8 | 2400±20% | 20Vrms |

| 328ST160 | Transmitter | 32.8±1.0 | 115dB at 32.8KHz | 2.5 | 2400±20% | 20Vrms |

| 328SR160 | Receiver | 32.8±1.0 | -67dB at 32.8KHz | 2.5 | 2400±20% | 20Vrms |

| 328ST180 | Transmitter | 32.8±1.0 | 117dB at 32.8KHz | 2.0 | 2400±20% | 20Vrms |

| 328SR180 | Receiver | 32.8±1.0 | -64dB at 32.8KHz | 2.0 | 2400±20% | 20Vrms |

| 400ST100 | Transmitter | 40.0±1.0 | 110dB at 40.0KHz | 2.5 | 1900±20% | 20Vpp |

| 400SR100 | Receiver | 40.0±1.0 | -70dB at 40.0KHz | 3.0 | 1900±20% | 20Vpp |

| 400ST120 | Transmitter | 40.0±1.0 | 115dB at 40.0KHz | 2.0 | 2400±20% | 20Vrms |

| 400SR120 | Receiver | 40.0±1.0 | -67dB at 40.0KHz | 2.0 | 2400±20% | 20Vrms |

| 400ST160 | Transmitter | 40.0±1.0 | 119dB at 40.0KHz | 2.0 | 2400±20% | 20Vrms |

| 400SR160 | Receiver | 40.0±1.0 | -65dB at 40.0KHz | 2.5 | 2400±20% | 20Vrms |

Closed Face Transducers

| Model Number | Description | Center Frequency (KHz) | Sensitivity Or SPL (min.) | Bandwidth (-6dB) (KHz) | Capacitance At 1KHz (pF) | Max. Continual Driving Voltage |

|---|---|---|---|---|---|---|

| 400ET250 | Transmitter | 25.0±1.0 | 113dB at 25.0KHz | 1.0 | 2400±20% | 15Vrms |

| 400ET250 | Receiver | 25.0±1.0 | -63dB at 25.0KHz | 1.0 | 2400±20% | 15Vrms |

| 328ET250 | Transmitter | 32.8±1.0 | 113dB at 32.8KHz | 1.0 | 2400±20% | 20Vrms |

| 328ER250 | Receiver | 32.8±1.0 | -67dB at 32.8KHz | 1.0 | 2400±20% | 20Vrms |

| 400ET080 | Transmitter | 40.0±1.0 | 100dB at 40.0KHz | 1.5 | 1700±20% | 15Vrms |

| 400ER080 | Receiver | 40.0±1.0 | -80dB at 40.0KHz | 2.0 | 1700±20% | 15Vrms |

| 400ET180 | Transmitter | 40.0±1.0 | 115dB at 40.0KHz | 1.5 | 2400±20% | 15Vrms |

| 400ER180 | Receiver | 40.0±1.0 | -70dB at 40KHz | 1.5 | 2400±20% | 15Vrms |

| 400ET250 | Transmitter | 40.0±1.0 | 115dB at 40.0KHz | 1.0 | 2400±20% | 20Vrms |

| 400ER250 | Receiver | 40.0±1.0 | -70dB at 40.0KHz | 1.0 | 2400±20% | 20Vrms |

Pulse Transit Transducers

| Model Number | Description | Center Frequency (KHz) | Sensitivity Or SPL (min.) | Bandwidth (-6dB) (KHz) | Capacitance At 1KHz (pF) | Max. Continual Driving Voltage |

|---|---|---|---|---|---|---|

| 400PT120 | Transceiver | 40.0±1.0 | 115dB/-68dB at f₀ | 2.0 | 2400±20% | 100Vp-p Tone Bursts (0.4ms) 2% Duty Cycle |

| 400PT160 | Transceiver | 40.0±1.0 | 117dB/-65dB at f₀ | 2.0 | 2400±20% | 100Vp-p Tone Bursts (0.4ms) 2% Duty Cycle |

| 400EP18A | Transceiver | 40.0±1.0 | 108dB/-75dB at f₀ | 1.5 | 1800±20% | 100Vp-p Tone Bursts (0.4ms) 2% Duty Cycle |

| 400EP14D | Transceiver | 40.0±1.0 | 103dB/-78dB at f₀ | 1.5 | 1250±20% | 100Vp-p Tone Bursts (0.4ms) 2% Duty Cycle |

| 400EP18D | Transceiver | 40.0±1.0 | 100dB/-80dB at f₀ | 1.2 | 1750±20% | 100Vp-p Tone Bursts (0.4ms) 2% Duty Cycle |

| 400EP250 | Transceiver | 40.0±1.0 | 113dB/-72dB at f₀ | 4.0 | 2400±20% | 100Vp-p Tone Bursts (0.4ms) 2% Duty Cycle |

| 480EP900 | Transceiver | 48.0±1.0 | 110dB/-80dB at 48KHz | 15.0 | 2400±20% | 100Vp-p Tone Bursts (0.4ms) 2% Duty Cycle |

Wide Bandwidth Transducers

| Model Number | Description | Center Frequency (KHz) | Sensitivity Or SPL (min.) | Bandwidth (-6dB) (KHz) | Capacitance At 1KHz (pF) | Max. Continual Driving Voltage |

|---|---|---|---|---|---|---|

| 400WB160 | Transceiver | 40.0±1.0 | 105dB/-72dB at 40.0KHz | 15.0 | 2400±20% | 20Vrms |

Mirror Bender Type Transducers

| Model Number | Description | Center Frequency (KHz) | Sensitivity Or SPL (min.) | Bandwidth (-6dB) (KHz) | Capacitance At 1KHz (pF) | Max. Continual Driving Voltage |

|---|---|---|---|---|---|---|

| 500MB120 | Dual | 43.0±4.0 | -55dB/100cm | 2.0 | 2400±20% | 20Vrms |

Matching Layer Transducers

Silicone Rubber Matching Layer

| Model Number | Description | Center Frequency (KHz) | Sensitivity Or SPL (min.) | Bandwidth (-6dB) (KHz) | Capacitance At 1KHz (pF) | Max. Continual Driving Voltage |

|---|---|---|---|---|---|---|

| 032SR750 | Transceiver | 32.0±3.0 | -58dB/25cm | 2.0 | 1400±20% | – |

| 043SR750 | Transceiver | 43.0±4.0 | .*20dB/-70dB at 125KHz | 10.0 | 5700±20% | 1500 Vp-p |

| 080SR365 | Transceiver | 80.0±8.0 | -57dB/50cm | 5.0 | – | – |

| 125SR250 | Transceiver | 125±10 | -58dB/25cm | 10.0 | 1250±20% | 700 Vp-p |

| 235SR130 | Transceiver | 235.0±10 | -60dB/25cm | 10.0 | 1120±20% | 80 Vp-p |

| 320SR093 | Transceiver | 320±10 | -65dB- | 10.0 | 270±20% | 50 Vp-p |

Glass Filled Epoxy Matching Layer

| Model Number | Description | Center Frequency (KHz) | Sensitivity Or SPL (min.) | Bandwidth (-6dB) (KHz) | Capacitance At 1KHz (pF) | Max. Continual Driving Voltage |

|---|---|---|---|---|---|---|

| 200GE180 | Transceiver | 200±10 | 20db/-75db | 1.5 | 580±20% | 50 Vp-p |

Additional Transducers and Components

Electrostatic Transducers

| Model Number | Description | Center Frequency (KHz) | Sensitivity Or SPL (min.) | Bandwidth (-6dB) (KHz) | Capacitance At 1KHz (pF) | Max. Continual Driving Voltage |

|---|---|---|---|---|---|---|

| 500ES290 | Transceiver | 50.0±1.0 | Sensitivity -43 dB(-63 dB) / SPL 116db | – | 600-700pF | 400Vp-p |

| 500ES430 | Transceiver | 50.0±1.0 | Sensitivity -42dB(-62 dB) / SPL 119db | – | 400-500pF | 400Vp-p |

Electronic Components

| Model Number | Description |

|---|---|

| SRM400 | Sonar Ranging Module |

| PW0268 | Sonar Custom ASIC IC |

| K4000001/2/3/4 | Matching Transformers |

Special Applications

| Model Number | Description |

|---|---|

| US040015 | Automotive Reverse Parking Aid Sensor |

| FS Series | Piezo Film (PVDF) FS-2513P,W, |

| 30402S,45402H, 45282H,60282H | High Power Transducers |

| M165D25 | Atomizing Ceramics Transducer |

| M2313500 | Atomizing Micro Nozzle Ultrasonic Transducer |

| GBD Series | Glass Break Detector Sensor GB-02W,B |

| 200LM450 | Under Water Transducer |

Assembled Units With Harness

Let’s Start Something new

Whether you have a specific requirement in mind or are seeking expert advice for an upcoming project, our team is here to guide you. Contact us today to explore how our transducers can be tailored to your unique needs.

Contact Information

Phone: (201)-354-7035 USA

Postal address: Advantage TMS Inc. 200 portland st , Boston MA 02114USA

Electronic mail General Information: info@advantagetms.com Sales: sales@advantagetms.com

Customer Support: support@advantagetms.com

Copyright (c) 2006 Advantage TMS/ Prowave, All rights reserved.

![]() Pro-Wave Distributor

Pro-Wave Distributor